New

#81

Thanks!

Thanks for the warning! The largest hole saw I ever used was to cut a 4" hole in the steel floor of a bus. That was the hardest sheet metal I ever had the misfortune of working with. That was around 20 years ago, when I was younger and healthier.

To be honest, cutting those two holes has me more nervous than a long-tailed cat in a room full of rocking chairs. Unfortunately, I don't have access to a drill press. I have a nice 1/2" electric drill but it has a lot of torque so methinks I'll use my 2 speed 1/2" 18v Ryobi instead. I can set it to the lower speed and just not pull the trigger all the way in to keep it even slower. I'll also set the clutch fairly loose so if the saw should snag or jam, the clutch will slip rather than yank the drill out of my hands. I'll put down a board to set the panel on, then stand on the panel to keep it from spinning while cutting the hole. If these are the last two large holes I ever have to cut, I'll be a happy camper.

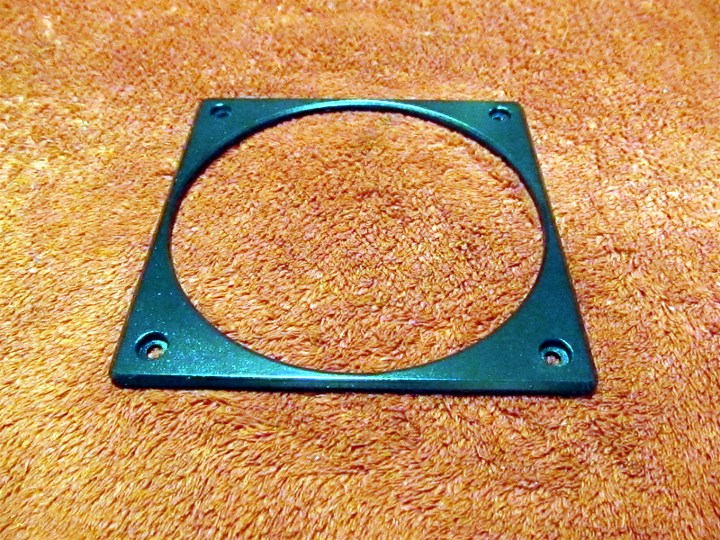

On another note...I was going to do this tomorrow but there was nothing on the boob tube tonight and I didn't feel like watching a movie, so I got ambitious and decided to cut the center out of the aluminum fan grill I got to cover up that ugly hole I had to make on the back of the case to get rid of the original grill and make room for a 140mm fan. I didn't take a before picture but this is what it looked like before my meatball surgery:

The bulls-eye center looks nice but does little to protect my fingers (and I bleed like a stuck pig due to my aspirin regimen). If I put a wire grill over it, it would look a bit dorky so the bulls eye had to go. I used a cutoff wheel in a Dremel tool to cut the legs of the bulls-eye as close to the edge as possible, which wasn't all that close since I didn't want to take a chance of messing up anything (yes, I am a coward...and proud of it), then used files to clean up the cuts (which took a lot of filing).

Here are the final results:

I still need to paint it to more or less match the case but I'm going to wait until Wednesday to do that since we are going to have a cool spell that will be better suited for painting than temps in the high 90s (it hit 100°F yesterday).

Quote

Quote