New

#271

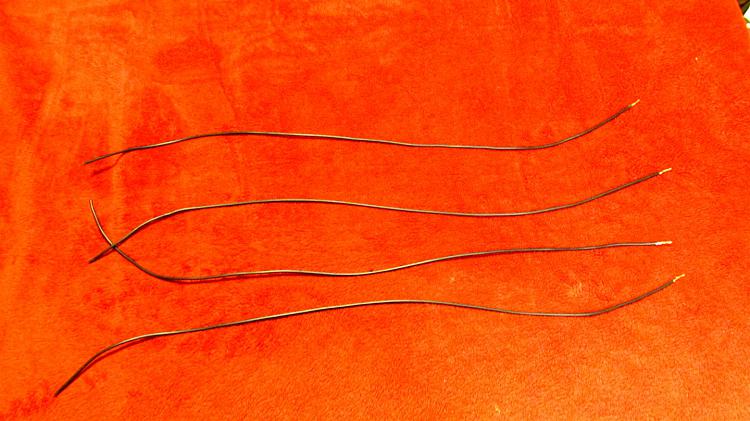

Well, I'm back to try to corrupt more of you with an even simpler cable. This is the one to power the sound card and, except for possible the SATA data cables, should be the last of the cables.

This time, I started with crimping the pins on the PSU end of the cable. I know I'm not a great photographer but how the big fat holy hairy heck did even I get three pins fairly well focused but the fourth so way out of focus?

The connector on the left is the one I just poked the pinned wires into. The one on the right is on the stock four pin Molex cable that came with the PSU.

Here, I'm starting to slip the sleeve onto the cable before putting the connector on the other end. the sleeve is a bit on the small size but I ran out of the correct size. One of the beauties of this brand of sleeving is it is so expandable.

This is a closer view. Before slipping the sleeve on, I used dots of Krazyglue roughly every couple of inches to keep the wires bundled and parallel.

Here is the finished cable. Kinda anticlimactic.

The cable has been more or less installed in this shot inside the case. The white arrows point to the cable itself. The blue (purple, whatever) arrow points at the front panel audio connector cable. That will be tied to the sound card power cable once I get the innards of my current rig transferred to this one.

And here is the cable as seen from the backside.

Hopefully, this is the last cable and the last major mod. I won't be doing much more for a couple of weeks when I will have more time to do the swap.

Quote

Quote